Tucson is no stranger to extremes. Chiefly, blazing heat, dry conditions, and occasional monsoon make for a challenging environment—not just for people but for your garage floor too. Epoxy floor coatings are the perfect solution for Tucson homeowners who need a surface that can withstand the harsh desert climate. However, as with anything built to last, the strength of your epoxy floor starts with preparation. One critical preparation step is how well the coating mix is prepared.

Just like crafting the perfect desert landscape, mixing epoxy is a precise process. Hence, the way it’s combined determines whether your floor will stand strong against the elements or crumble under pressure. Let’s take a look at why mixing epoxy matters so much in Tucson.

Epoxy Floor Coatings: The Importance of the Mix

Epoxy is made up of two main components: Part A (the resin) and Part B (the activator). When these two come together, a chemical reaction takes place that transforms the liquid into a solid, durable surface. However, the strength of that transformation depends on how precisely the parts are mixed.

In Tucson’s dry heat, an improperly mixed epoxy can lead to issues like cracking, peeling, or a lack of proper adhesion to the concrete. Hence, the mix is where it all begins.

Here are some key reasons why the mix is essential:

- Firstly: Precision in Ratios – The balance between Part A and Part B needs to be exact. Common ratios include 1:1, 2:1, 3:2 or even 4:1. If these aren’t followed closely, the floor might not cure properly, leading to early wear and tear.

- Secondly: Weather Impact – Tucson’s extreme heat and humidity can affect the curing process, making it crucial that the mix is prepared with the local climate in mind.

- Thirdly: Durability – The right mix ensures your epoxy floor is resistant to common desert issues like moisture infiltration, heat-induced cracks, and wear from heavy use.

Epoxy Floor Coatings: Avoiding Common Pitfalls in Epoxy Mixing

There are a few common mistakes that can ruin an epoxy floor, especially in a place like Tucson. Here’s what you want to avoid:

- Inaccurate Measuring: Even a small mistake in measuring the components can compromise the entire project. The wrong ratio can leave your floor vulnerable to cracking and peeling under Tucson’s intense heat.

- Wrong Equipment: Using the wrong tools—like a basic stir stick—won’t give you the smooth, bubble-free mix needed for a strong epoxy floor. A high-speed drill with the right mixing blade is key to ensuring uniformity.

- Mixing Different Products: Combining products from different epoxy lines can lead to improper bonding. Stick to one product line to ensure everything works together as it should.

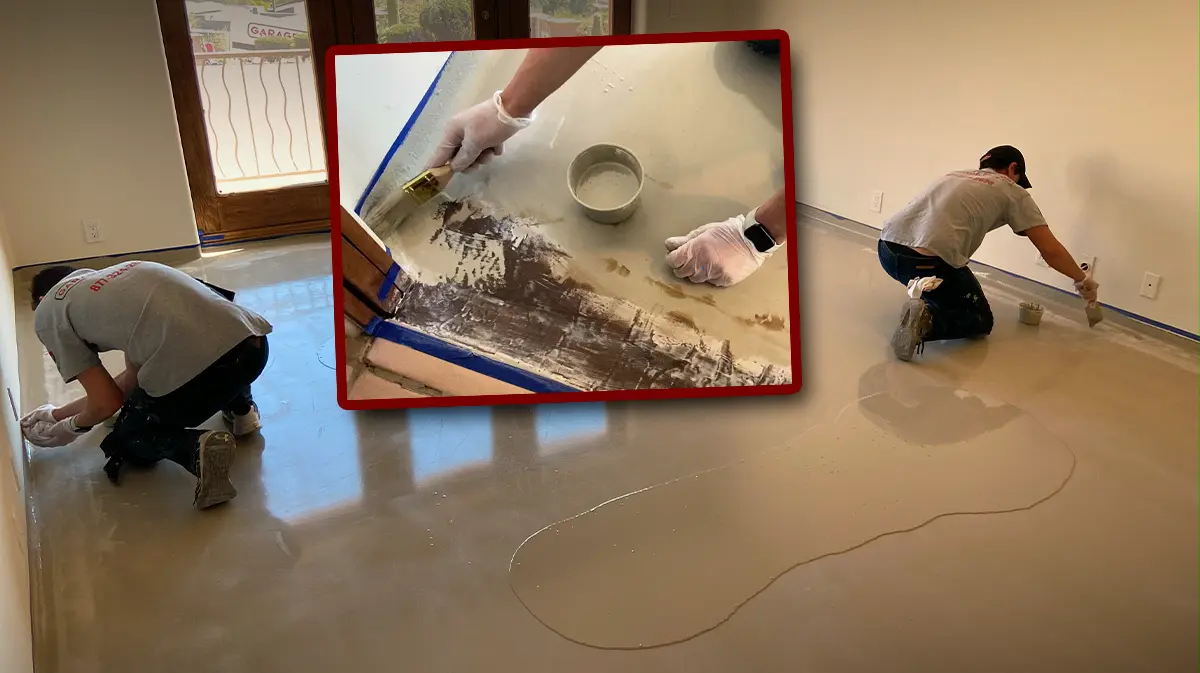

Epoxy Floor Coatings: Our Mixing Process – Step-by-Step Precision

We know how important precision is for a floor that lasts in Tucson’s unique environment. Here’s how we handle epoxy mixing, step by step:

- Start with Part A: If the epoxy is pigmented, we begin by thoroughly mixing Part A to ensure the color is evenly distributed. This is important for a smooth, consistent finish, especially in a place like Tucson, where sunlight can quickly reveal imperfections.

- Slowly Add Part B: After mixing Part A, we carefully add Part B, making sure to stir it slowly and evenly. This prevents air bubbles from forming (add it to the list of common pitfalls we see!), which could weaken the epoxy’s strength.

- Batch Mixing for Consistency: If multiple containers of Part A are needed, we batch mix them together to ensure consistency in color and texture. This is especially crucial for larger garages where uniformity is key.

- Controlled Environment: We ensure the mixing environment is clean and dust-free—Tucson’s dry, dusty climate makes it important to keep contaminants out of the mix. Even a small amount of dust can impact the adhesion and durability of the epoxy.

Why Tucson Homeowners Should Trust the Pros

In Tucson, where temperatures regularly soar over 100 degrees, DIY epoxy projects are risky. Without the right knowledge and equipment, the extreme heat can cause the epoxy to cure too quickly or not bond properly to the concrete. That’s why it’s important to leave it to the experts.

We tailor our epoxy mixing and application process to Tucson’s unique desert environment. Our experience ensures that your garage floor will be durable, resistant to the elements, and ready to handle anything from monsoon rains to scorching summer days.

The Bottom Line: Built for Tucson’s Desert Climate

Your garage floor deserves the same level of care and durability as any other part of your home, especially in Tucson’s challenging climate. With a professionally mixed and applied epoxy coating, you’ll get a floor that’s not only beautiful but also built to last in the desert heat.

Trust us to get the job done right. Our precision, expertise, and local knowledge make us the best choice for Tucson homeowners who want a garage floor that can handle the heat—and look great doing it.