Tucson’s desert climate brings unique challenges when it comes to epoxy flooring. The intense heat, dry conditions, and occasional monsoons can be tough on floors, so it’s essential to understand the terms that describe the protective coatings available. Here’s a breakdown of common epoxy flooring terms categorized for easy reference.

Epoxy Flooring Terms: Coating Types

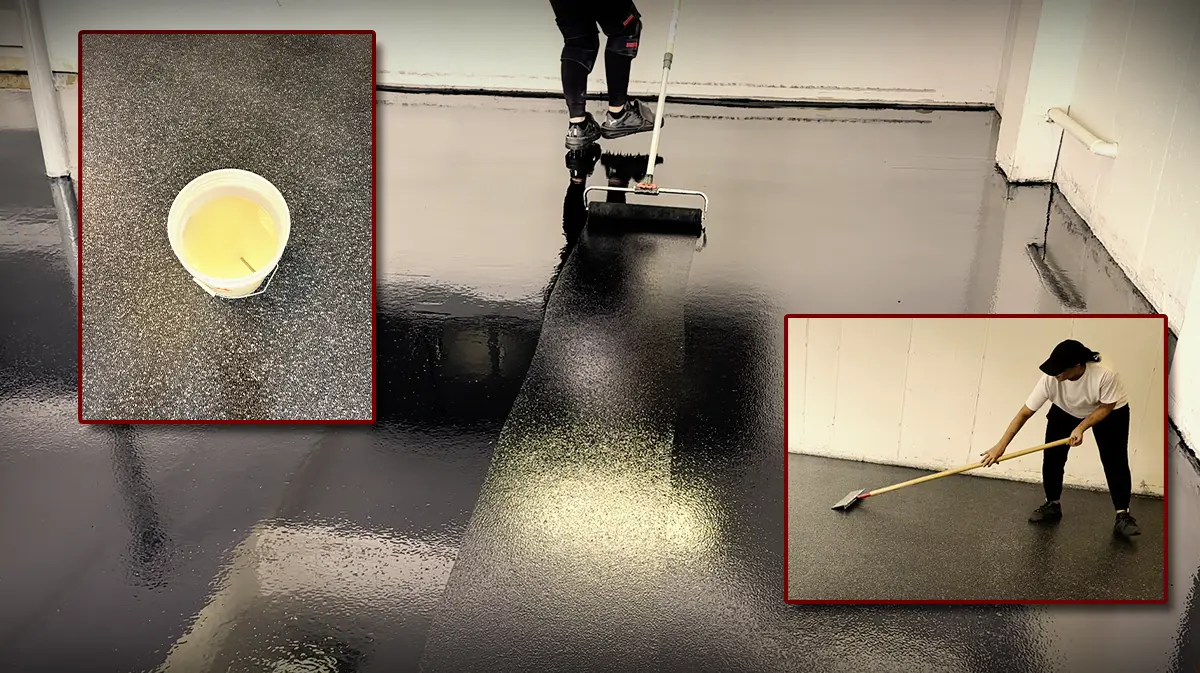

- Epoxy Coating: Epoxy coatings are one of multiple types of 2-component (Parts A & B) concrete coatings. Epoxies have slow-cure and high-build properties. Although they can be used as color coats and top coats, they are best suited as direct-to-concrete primers. Precisely because they cure slowly and go down thickly, they are the best moisture-mitigating coatings. Even in Tucson, a moisture-mitigating epoxy coating is the best choice as primer. It’s essential for protecting concrete floors from cracking or damage due to moisture vapor transmission. However, epoxies do have an Achilles heel. They fade and amber if exposed to sunlight, so if used as a primer coat, they must be covered with flakes or color coat. If used as a color coat or top coat, they are restricted to interior installations.

- Polyurethane Coating: Polyurethanes are used as color or topcoats. They add a layer of protection against chemical spills, abrasions, and UV rays. They are “older technology” coatings that can be odorous and are not for use in garages (they’re susceptible to plasticizer migration from hot car tires). However, polyurethanes are excellent for exterior applications including patios and walkways, even in areas exposed to direct sunlight (critical in Tucson’s harsh desert climate).

- Polyaspartic Coating: With fast-cure properties, polyaspartic coatings are a great option as top coats for garages, commercial and exterior spaces. Polyaspartics are UV-stable, meaning they resist yellowing even in Tucson’s bright, year-round sunshine. They also provide extreme chemical resistance, making them ideal for use as top coats in garages (using an epoxy would not be as resilient). An epoxy primer with one or more polyaspartic topcoats produces the most durable floor coatings (and provide the longest warranties).

Epoxy Flooring Terms: Additives and Adaptations

- Flake System: A flake system is a concrete coating system in which decorative flakes have been broadcast into the “wet” primer coat. The flakes embed into the epoxy primer, adding depth and texture (and some grip), enhancing the visual appeal of the floor.

- Moisture Mitigation: Despite the desert environment, Tucson does experience seasonal monsoons, making moisture mitigation important. Moisture trapped in concrete, beneath a floor coating, creates a hydrostatic pressure that pushes up on the coating. The entire layered coating system is only as strong as its primer coat! This is why applying a moisture vapor barrier in the form of a moisture-mitigating epoxy is critical. Using wafer-thin polyurea or polyaspartic coatings as primers can cause peeling or bubbling.

Epoxy Flooring Terms: Colloquial Terms

- “Concrete Paint”: Homeowners sometimes use the term “concrete paint” when talking about epoxy, but true paint doesn’t offer the same durability. While it can give a garage or patio a quick aesthetic fix, it lacks the chemical bonding properties of epoxy and won’t last as long in Tucson’s climate.

- “Garage Floor Coating”: In Tucson, “garage floor coating” refers to the layered epoxy or polyaspartic coatings used to protect garage floors. These coatings are necessary in desert environments to prevent damage from moisture and the intense sun and high temperatures.

Conclusion

In Tucson, epoxy flooring must withstand both intense heat and seasonal moisture. Understanding these terms will help you select the best coating for your space, ensuring that your floor remains durable and attractive for years to come. Whether you’re protecting your garage or upgrading a patio, these coating options offer both strength and style.